Inspec Solutions Ltd was awarded a project to develop a computer-based visual object detection and tracking system. The tracking system is installed on the Festo Cyber-Physical Lab (CP Lab), located in the University’s Diamond building and enables the real-time tracking of objects as they move through the CP Lab manufacturing system.

The CP Lab is a compact Industry 4.0 learning system that allows the University to simulate advanced, CAM manufacturing processes. The CP Lab consists of three elements: two fixed work cells and an autonomous vehicle that travels between each of the two work cells. Each work cell consists of four stations that represent a stage in the manufacturing process, with each station being equipped with radio-frequency identification (RFID) readers. Pallets identified by unique RFID tags are served to each station via conveyors, delivering the components to supply the process. The end-to-end process is designed to simulate the manufacturing of mobile phones.

Adhering to Industry 4.0 design recommendations provides a real-time view of the manufacturing process, although it was realised that in this manufacturing process, pallets could only be tracked when they arrived at a station, leaving voids in the tracking information of the process state. In order to bridge the gaps, Inspec Solutions provided a vision tracking system to deliver the holistic view of the process the research engineers in the CP Lab desired.

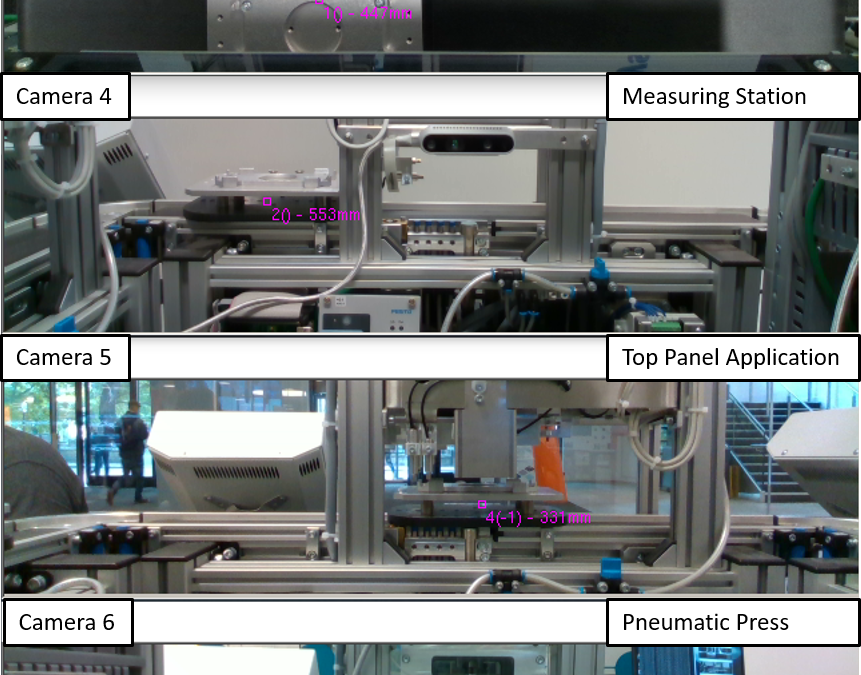

Cameras mounted on each station in the CP Lab cover the entire length of each and every conveyor within the manufacturing process, including each of the work cell stations. Using advanced machine learning algorithms and models, the tracking application reads camera image frames and self-trains to detect pallets, thereby calculating the exact locations of each within the process. This real time detection and tracking of pallets across the entire CP Lab conveyor system provides full visibility of the status of the end-to-end manufacturing process.

The vision tracking system supplied included all hardware and a bespoke software application designed and implemented by the software team at Inspec Solutions.

The additional information provided by the vision-based tracking system is allowing the University to develop an accurate digital twin of the CP Lab manufacturing process. Through the development of the digital twin system increases value of the CP Lab as a research tool, and also provides a platform to develop the CP Lab into a cutting edge Industry 4.0 manufacturing system where physical objects and twin models interact in a mutually beneficial manner.